When you consider parallel shaft drive gearbox design, the importance of custom solutions becomes clear. You can optimize efficiency and performance by tailoring gear ratios, materials, and dimensions to specific applications. These bespoke configurations not only enhance reliability but also pave the way for future modifications without the need for complete replacements. As industries evolve, the demand for these personalized designs grows. What challenges and opportunities lie ahead in this ever-changing landscape?

Importance of Custom Design

Recognizing the unique requirements of each application, custom design in Parallel Shaft Drives gearbox development is crucial for optimal performance. When you opt for a tailored gearbox solution, you ensure that the design aligns perfectly with your specific needs, whether it’s for a high-speed application, heavy load handling, or limited space conditions. Off-the-shelf gearboxes mightn’t provide the efficiency or durability you need, leading to potential failures and costly downtimes.

By investing in a custom design, you gain the flexibility to choose materials, gear ratios, and configurations that best suit your operational demands. You’re not just adapting; you’re enhancing your machinery’s capabilities.

With personalized designs, you can optimize energy consumption, reduce noise levels, and improve overall reliability, which translates into smoother operations and increased productivity.

Additionally, custom-designed gearboxes allow for future scalability. As your needs evolve, having a gearbox that can be modified or expanded helps you stay ahead, eliminating the need for complete replacements.

Key Features of Parallel Shaft Gearboxes

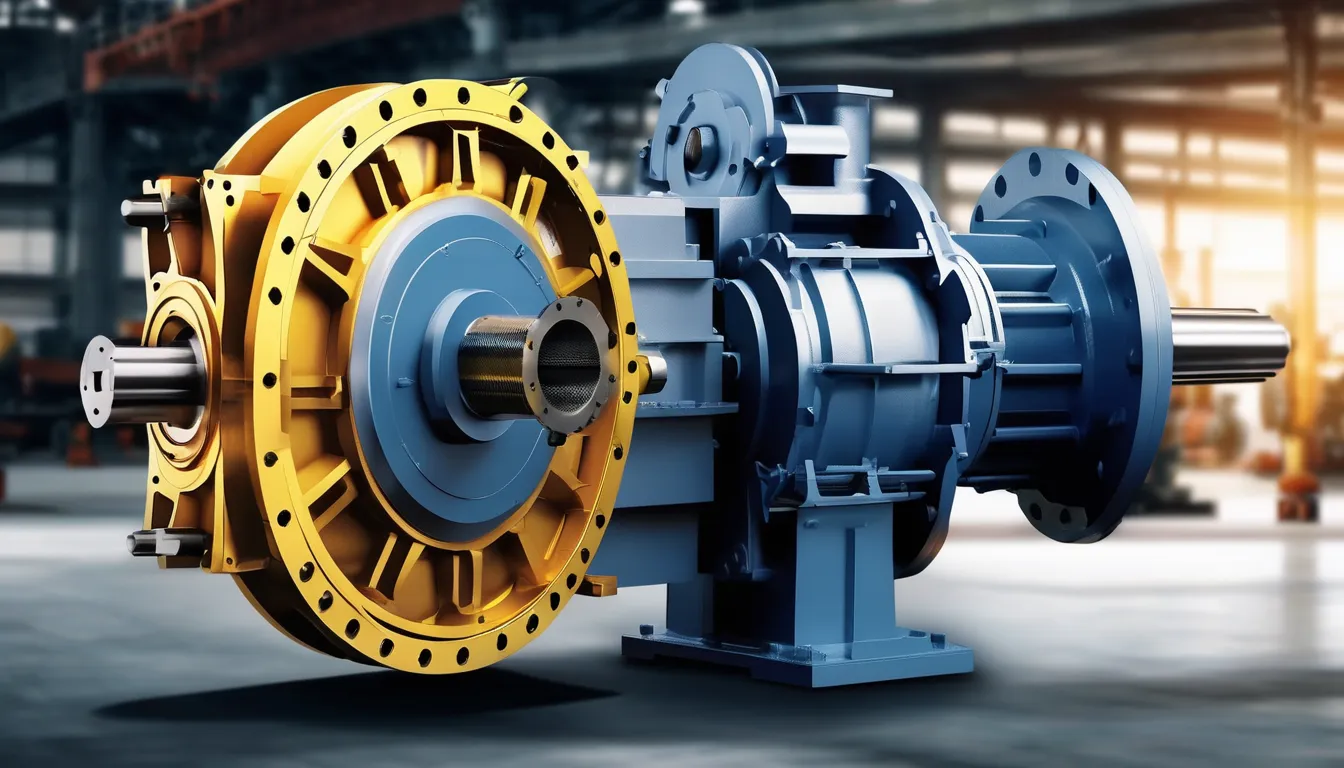

Understanding the key features of parallel shaft gearboxes can significantly enhance your machinery’s performance. These gearboxes are designed with parallel shafts that allow for efficient power transmission and compact design, making them ideal for various applications.

One of the standout features is their high torque capacity, which enables you to handle demanding loads without compromising reliability. You’ll also appreciate their versatility; parallel shaft gearboxes can be configured in multiple ways to suit your specific needs.

Another important aspect is their smooth operation. The design minimizes vibrations and noise, contributing to a quieter workspace and extending the life of both the gearbox and connected equipment.

Additionally, these gearboxes often have a high efficiency rating, meaning less energy is wasted during operation.

Ease of maintenance is another key feature; many parallel shaft gearboxes come with user-friendly designs that simplify inspection and servicing. This can save you both time and money in the long run.

Applications in Various Industries

Parallel shaft gearboxes find applications across a wide range of industries, making them essential components in various machinery.

In manufacturing, you’ll find these gearboxes driving conveyor systems and robotic arms, ensuring smooth and efficient operations. Their compact design and high torque capacity make them ideal for heavy-duty applications, where reliability is key.

In the automotive sector, parallel shaft gearboxes help in power transmission, enhancing vehicle performance. Whether in electric vehicles or traditional combustion engines, they contribute to improved efficiency and responsiveness.

You might also notice them in construction equipment, where they power cranes and excavators, allowing for precise control of heavy loads.

Additionally, the food and beverage industry relies on parallel shaft gearboxes for mixing, packaging, and processing machinery. Their ability to withstand harsh environments and maintain consistent performance is vital in these settings.

In the renewable energy sector, such as wind turbines, they play a crucial role in converting rotational energy efficiently.

Benefits of Tailored Solutions

Tailored solutions in gearbox design offer a range of significant benefits that can enhance performance and efficiency across various applications. By customizing your gearbox to fit specific requirements, you ensure optimal functionality, which can lead to improved productivity.

You’ll notice that a well-designed gearbox minimizes energy loss, allowing your machinery to operate more effectively.

Another advantage is the increased reliability that comes from tailored designs. When you address the unique conditions and demands of your application, you reduce the risk of failure, thus extending the lifespan of your equipment.

This reliability translates to lower maintenance costs and less downtime, which are crucial for maintaining your operational efficiency.

Moreover, tailored solutions can contribute to a more compact and lightweight design. By eliminating unnecessary components, you can create a gearbox that’s easier to integrate into your existing systems.

This not only saves space but also enhances overall performance.

Future Trends in Gearbox Design

Embracing advancements in technology is essential for the future of gearbox design, as innovations continue to reshape the industry.

You’ll find that several key trends are emerging, and staying ahead means adapting to these changes.

Here are four trends you should watch closely:

- Additive Manufacturing: 3D printing is revolutionizing how gearboxes are produced, allowing for complex geometries that traditional methods can’t achieve.

- Smart Gearboxes: With the integration of IoT technology, gearboxes are becoming smarter. Sensors can monitor performance in real-time, enabling predictive maintenance and reducing downtime.

- Lightweight Materials: Advances in materials science are leading to lighter yet stronger components. Using these materials can improve efficiency and performance in various applications.

- Modular Designs: Customizable, modular gearbox systems allow for easier upgrades and maintenance, ensuring that your equipment stays relevant and efficient over time.

Conclusion

In conclusion, custom solutions in parallel shaft drive gearbox design are essential for optimizing performance across various applications. By choosing tailored configurations, you ensure enhanced energy efficiency, reduced noise, and improved reliability. These bespoke designs not only meet your specific needs but also allow for future scalability, keeping your operations adaptable. Embracing personalized gearbox solutions can significantly boost productivity and extend the lifespan of your equipment, making it a smart investment for any industry.